Detailed Procedure

Targets were prepared from deuterated polyethylene powder. The procedure employed is modified from that of C. M. Bartle and H. O. Meyer Nucl. Instr. Meth. 1973, 112, 615 and the procedure supplied by K. Fletcher (Geneseo).

| Preparation of films. A hot solution of powdered DPE is poured onto a warm microscope slide that was previously coated with a film of soap solution (Figure 1). |  |

| Figure 3. The finished product. |

Film Thickness. Rough estimates of the thickness of the films were made assuming that the density of the material is the same as that of bulk powdered DPE (0.94 g/cm3). The mass of a film with a predetermined area was found using an analytical balance. Data for four films prepared using different masses of powdered DPE are shown below.

| DPE powder, mg | film mass, g | film area, cm2 | mg/cm2 | film thickness, mm | film thickness, mils |

| 40 | 9.0 | 15.00 | 0.60 | 0.0064 | 0.25 |

| 60 | 24.7 | 18.75 | 1.32 | 0.0140 | 0.55 |

| 70 | 29.8 | 17.02 | 1.75 | 0.0186 | 0.73 |

| 80 | 26.6 | 13.75 | 1.93 | 0.0206 | 0.81 |

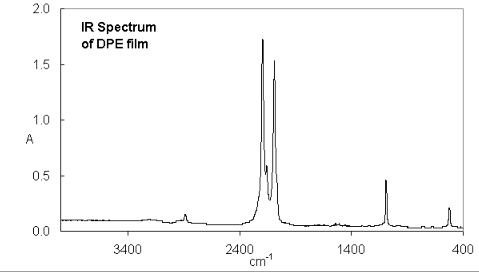

Beers law was used to obtain a better estimate of the DPE film thickness. Each of the films was placed in an FT-IR spectrometer and the absorbance of IR radiation was measured at 2091cm-1, which corresponds to the nC-D stretch region of the spectrum.

|

However, the absorbance must be 0 in the absence of PDE and so the film thicknesses are offset by a factor corresponding to the x-intercept. The corrected data are displayed below:

| DPE powder, mg | Corrected thickness, mil |

| 40 | 0.51 |

| 60 | 0.81 |

| 70 | 0.99 |

| 80 | 1.07 |

These results show that the density of the DPE film is less than that of powdered PE. The densities of the films with the thicknesses determined as described above are

| mils | mg/cm2 | d (g/cm3) |

| 0.51 | 0.60 | 0.46 |

0.81 | 1.32 | 0.64 |

| 0.99 | 1.75 | 0.69 |

| 1.07 | 1.93 | 0.71 |

IR spectral analysis enables us to quickly obtain an estimate of the thickness of the film.