SEM Imaging Process

The Imaging Process

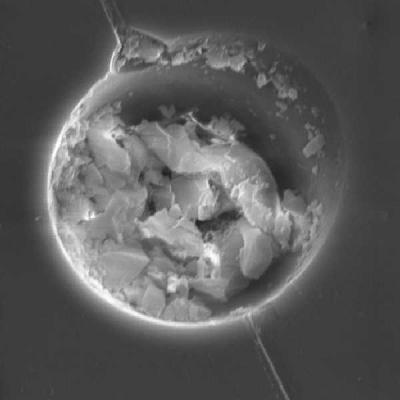

In order to view objects with the SEM, the objects need to be plated with a conductive surface (often Au or Graphite). A gold palladium target and a sputtering machine is used for all the imaging here. However, if the surface is disturbed (possibly by rubbing off the gold for further etching) after the plating, then the layer of gold can flake up and collect into the pits. This caused the pits to be filled in with a strange-looking “gunk” which was later determined by X-ray analysis to be gold flakes.

This is what the pits look like when filled in with this strange “gunk.”

|

|

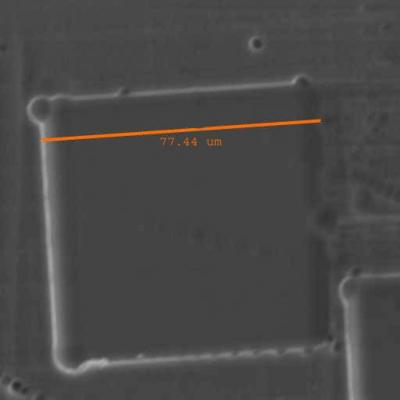

The SEM uses a beam of 15 KeV electrons. This is too much for the surface of CR-39 and it gets damaged as imaging occurs. A square of damage appears at the scanned region and although it's not deep enough to make much of a difference in pit size, it's still noticeable. A lower energy beam can be used but this yields poorer image quality. |

|

|